- Home

- about us

- Service

- Industries

-

Products

- Automotive Components & Parts

- Medical Instrument Components & Parts

- Motorcycles Components & Parts

- Coffee Machine Components & Parts

- Remanufactured Railway Components & parts

- Integrated Chassis & Cabinets

- Robotics & Automation Components & Parts

- High Precision Valve Components & Parts

- Magnet Components & Parts

- Get a free quote

- News

- Contact us

Cell/WhatsApp: +8618116092892

Email: info@addtechintel.com

Website:www.addtechintel.com

Address:Room C218, Building D, No. 1928, Liuxiang Road, Jiading District, Shanghai, China

Service

- CNC machinging

- CNC milling

- CNC Turning

- Casting

- Stamping

- Fabrication

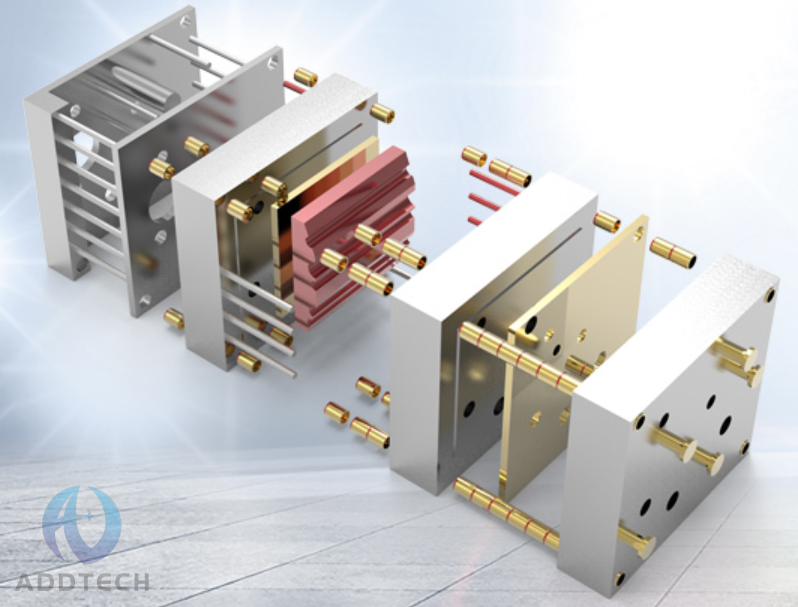

- Plastic injection molding

- Rubber Compression Molding

- Compression Molding Forming

- Integrated Circuit

Products

- Automotive Components & Parts

- Medical Instrument Components & Parts

- Motorcycles Components & Parts

- Coffee Machine Components & Parts

- Remanufactured Railway Components & parts

- Integrated Chassis & Cabinets

- Robotics & Automation Components & Parts

- High Precision Valve Components & Parts

- Magnet Components & Parts

Cell/WhatsApp: +8618116092892

Email: info@addtechintel.com

Website:www.addtechintel.com

Address:Room C218, Building D, No. 1928, Liuxiang Road, Jiading District, Shanghai, China

Service

- CNC machinging

- CNC milling

- CNC Turning

- Casting

- Stamping

- Fabrication

- Plastic injection molding

- Rubber Compression Molding

- Compression Molding Forming

- Integrated Circuit

Products

- Automotive Components & Parts

- Medical Instrument Components & Parts

- Motorcycles Components & Parts

- Coffee Machine Components & Parts

- Remanufactured Railway Components & parts

- Integrated Chassis & Cabinets

- Robotics & Automation Components & Parts

- High Precision Valve Components & Parts

- Magnet Components & Parts